Advantages

Corrosion and chemical stability

It possesses the absolute stability to exposure to humidity, chemically aggressive and alkaline conditions, does not rot and rust. It does not provoke the concrete destruction.

Strength

The tensile strength indexes are three times higher the ones of metal grid.

Low heat conduction

It reduces the heat losses in building, excludes the formation of cold bridges, and considerably increases the building power efficiency.

Lightness

Low specific gravity promotes the reduction of delivery and installation costs, as well as loading-unloading man-hour costs. It does not load the structure itself

Durability

The service life is three times higher than the one of metal grid, and comprises 80 years and more.

Complete dielectric and radio transparent abilities

It does not create radio interferences, as well as the ones for mobile communication and for quality of Internet communication.

Order PRO-GRID composite grid directly from the factory

When ordering a composite grid from the factory, you are guaranteed to get the best price on the market. Call 8 (800) 500-57-08 or leave your number and we will call you back as soon as possible.

Successfully sent

Our specialist will contact you soon

Projects

Comparison of steel and composite reinforcement

Tensile strength

Modulus of elasticity

Modulus of elongation

Density (weight)

Length

Heat-conduction

Electricity-conduction

Durability

Composite

1000 MPa

40-50 HPa

2,2%

1,9 t/m3

Any

Low

Dielectric

Up to 80 years

Metallic

390 МПа

180-200 HPa

25%

7 t/m3

6 and 12 m

High

High

Up to 40 years

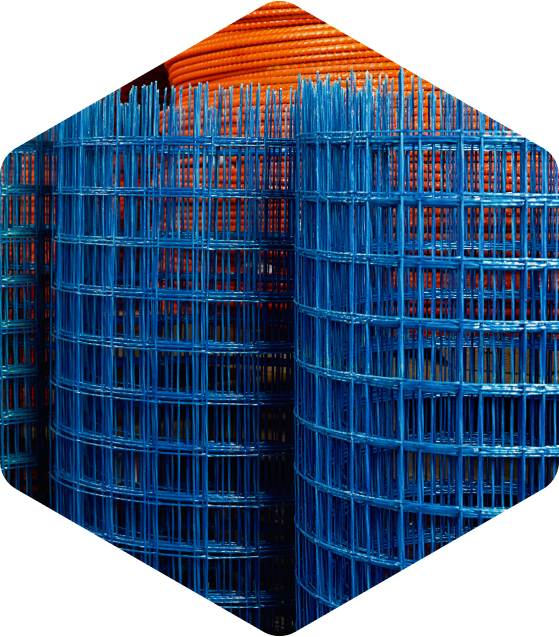

Packing versions of composite grid

New approach in composite grid production

by means of sew-knit technology. As distinct from ordinary grid of superimposed type, the PRO GRID is invulnerable in areas of cross-type connections. It endures the load of up to 650 kg and more.

-

Sew-knit technologyIncreases the material strength in areas of cross-type connections.

-

Counter-torsion of longitudinal barProvides “work” of the material in several directions.

-

Axial torsion of longitudinal and lateral connectionsIncreases the composite density by making the material more stable to destructive effects.

-

High-quality compositionDoes not have nylon, polypropylene threads, and other foreign elements in its composition.

Related videos

Profit in usage of composite materials

Tell us about your project, and find out how much you can save

Successfully sent

Our specialist will contact you soon

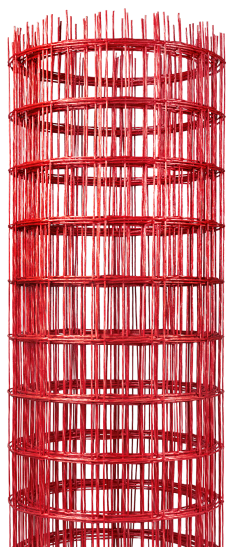

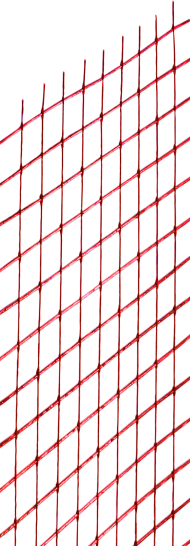

Composite grid PRO-GRID (red)

Rod diameter3 mm

Cell size100*100

Width0.5 and 1.0 m

Ordered lengthany

Length of reelfrom 10 to 400 m

Service lifeup to 80 years

Application:

Civil construction, road construction, maritime and seaside structures, agriculture and stockbreeding, industry

Minimal delivery volume is — 1000 m

If you want to purchase the less batch, please fill in the form, and we will find the closest retail point for you.

We guarantee the best price on the market! Found cheaper — let us know about it and we will find the best solution!

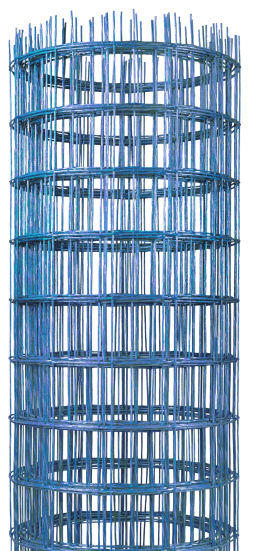

In reels

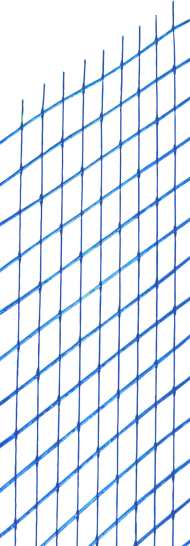

In cards

Minimal delivery volume is — 1000 m

If you want to purchase the less batch, please fill in the form, and we will find the closest retail point for you.

We guarantee the best price on the market! Found cheaper — let us know about it and we will find the best solution!

Successfully sent

Our specialist will contact you soon

Successfully sent

Our specialist will contact you soon

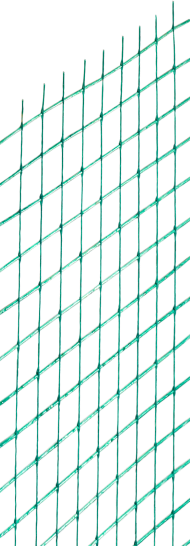

PRO GRID composite grid(green)

Rod diameter2,5 mm

Cell size100*100

Width0,5 и 1,0 м

Ordered lengthany

Length of reelот 10 до 400 м

Service lifeup to 80 years

Application:

Civil construction, road construction, maritime and seaside structures, agriculture and stockbreeding, industry

Minimal delivery volume is — 1000 m

If you want to purchase the less batch, please fill in the form, and we will find the closest retail point for you.

We guarantee the best price on the market! Found cheaper — let us know about it and we will find the best solution!

In reels

In cards

Minimal delivery volume is — 1000 m

If you want to purchase the less batch, please fill in the form, and we will find the closest retail point for you.

We guarantee the best price on the market! Found cheaper — let us know about it and we will find the best solution!

Successfully sent

Our specialist will contact you soon

Successfully sent

Our specialist will contact you soon

PRO GRID composite grid(blue)

Rod diameter2 mm

Cell size50*50, 100*100

Width0,5 и 1,0 м

Ordered lengthany

Length of reelот 10 до 400 м

Service lifeup to 80 years

Application:

Civil construction, road construction, maritime and seaside structures, agriculture and stockbreeding, industry

Minimal delivery volume is — 1000 m

If you want to purchase the less batch, please fill in the form, and we will find the closest retail point for you.

We guarantee the best price on the market! Found cheaper — let us know about it and we will find the best solution!

In reels

In cards

Minimal delivery volume is — 1000 m

If you want to purchase the less batch, please fill in the form, and we will find the closest retail point for you.

We guarantee the best price on the market! Found cheaper — let us know about it and we will find the best solution!

Successfully sent

Our specialist will contact you soon

Successfully sent

Our specialist will contact you soon

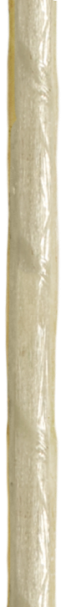

Supports for plants

Rod diameterany

Rod lengthany

Ordered lengthany

Service lifeabout 80 years old

Suppliedbundled 50 pcs

Applicationreusable

Application:

Agriculture

Minimal delivery volume is — 1000 m

If you want to purchase the less batch, please fill in the form, and we will find the closest retail point for you.

We guarantee the best price on the market! Found cheaper — let us know about it and we will find the best solution!

Minimal delivery volume is — 3000 m

If you want to purchase the less batch, please — fill out the form and we will find the nearest retail outlet for you.

We guarantee the best price on the market! Found cheaper — let us know about it and we will find the best solution!

Successfully sent

Our specialist will contact you soon

Successfully sent

Our specialist will contact you soon

Arches for hothouses

Rod diameterany

Rod lengthany

Ordered lengthany

Service lifeabout 80 years old

Suppliedbundled 50 pcs

Applicationreusable

Application:

Agriculture

Minimal delivery volume is — 5000

If you want to purchase the less batch, please fill in the form, and we will find the closest retail point for you.

We guarantee the best price on the market! Found cheaper — let us know about it and we will find the best solution!

Minimal delivery volume is — 5000 m

If you want to purchase the less batch, please fill in the form, and we will find the closest retail point for you.

We guarantee the best price on the market! Found cheaper — let us know about it and we will find the best solution!

Successfully sent

Our specialist will contact you soon

Successfully sent

Our specialist will contact you soon

Pickets for electrical shepherds

Rod diameterany

Rod lengthany

Ordered lengthany

Service lifeabout 80 years old

Suppliedbundled 50 pcs

Applicationreusable

Application:

Agriculture

Minimal delivery volume is — 1000 m

If you want to purchase the less batch, please fill in the form, and we will find the closest retail point for you.

We guarantee the best price on the market! Found cheaper — let us know about it and we will find the best solution!

Minimal delivery volume is — 3000 m

If you want to purchase the less batch, please fill in the form, and we will find the closest retail point for you.

We guarantee the best price on the market! Found cheaper — let us know about it and we will find the best solution!

Successfully sent

Our specialist will contact you soon

Successfully sent

Our specialist will contact you soon

Composite fixtures 10mm

Special series for network Leroy Merlin

Special series for network Leroy Merlin

weight l.m., gr.

Winding pitch (mm)10

Service lifeup to 80 years

Possible length

What is supplied

Application:

Civil construction, road construction, maritime and seaside structures, agriculture and stockbreeding, industry

Minimal delivery volume is — 3000 m

If you want to purchase the less batch, please fill in the form, and we will find the closest retail point for you.

We guarantee the best price on the market! Found cheaper — let us know about it and we will find the best solution!

Minimal delivery volume is — 3000 m

If you want to purchase the less batch, please fill in the form, and we will find the closest retail point for you.

We guarantee the best price on the market! Found cheaper — let us know about it and we will find the best solution!

Successfully sent

Our specialist will contact you soon

Successfully sent

Our specialist will contact you soon

Successfully sent

Our specialist will contact you soon

Successfully sent

Our specialist will contact you soon

Successfully sent

Our specialist will contact you soon